Maximizing the Lifespan of Flex Seal Spray on a Roof sheds light on the durability and effectiveness of Flex Seal Spray as a roofing solution. This article examines the longevity of this innovative product and provides valuable insights on how to extend its lifespan. Explore the benefits of using Flex Seal Spray on your roof and discover essential maintenance tips that will ensure its long-lasting performance.

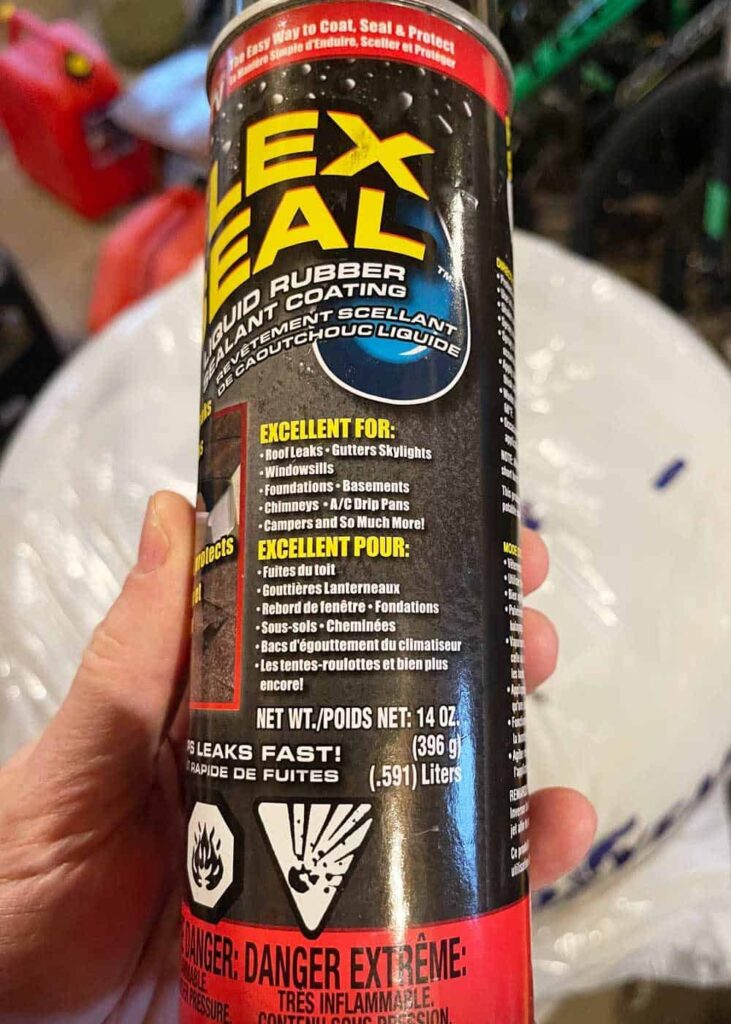

This image is property of howlongdoesrooflast.com.

Understanding Flex Seal Spray

What is Flex Seal Spray?

Flex Seal Spray is a versatile waterproofing product that comes in a pressurized can. It is a rubberized coating that can be sprayed onto a variety of surfaces, including roofs, to create a watertight seal. Flex Seal Spray is designed to be easy to use and provides a long-lasting, durable solution for sealing and protecting roofs.

How does Flex Seal Spray work?

Flex Seal Spray works by forming a thick, flexible rubber coating when it is applied to a surface. As the spray dries, it creates a tight seal that protects against water leaks and can help to prevent further damage to the roof. The rubberized coating is designed to expand and contract with the roof’s movement, making it an ideal solution for areas prone to temperature fluctuations or structural shifts.

Where can Flex Seal Spray be used?

Flex Seal Spray can be used on a wide range of surfaces, including roofs made of asphalt, metal, concrete, wood, PVC, and more. It can be applied to both flat and sloped roofs, making it suitable for various types of roof structures. Additionally, Flex Seal Spray can be used on other areas of the roof, such as flashing, gutters, and vents, to provide additional protection against leaks.

Benefits of using Flex Seal Spray on a roof

Using Flex Seal Spray on a roof offers several benefits. Firstly, it provides a quick and easy solution for repairing and preventing leaks, saving homeowners time and money compared to more extensive roof repairs. Additionally, Flex Seal Spray is a versatile product that can be used on different types of roofs, making it a convenient option for various applications. The rubberized coating created by Flex Seal Spray is also resistant to extreme weather conditions, UV radiation, and can last for an extended period, ensuring long-term protection for the roof surface.

Preparing the Roof Surface

Cleaning the roof

Before applying Flex Seal Spray, it is crucial to clean the roof surface thoroughly. Remove any debris, such as leaves, branches, or loose shingles, using a broom or a blower. Inspect the roof for any signs of mold, mildew, or algae growth, and clean these areas with a suitable roof cleaner or a mixture of water and bleach. Cleaning the roof surface ensures that the Flex Seal Spray adheres properly and maximizes its effectiveness.

Repairing any existing damage

Inspect the roof for any existing damage, such as cracks, holes, or damaged shingles. Repair these areas using appropriate roofing materials and techniques before applying Flex Seal Spray. It is essential to address any structural issues to prevent further damage and ensure the longevity of the Flex Seal Spray coating.

Ensuring the roof is dry and free of debris

Before applying the Flex Seal Spray, ensure that the roof surface is dry and free of debris. If there is any moisture present, use a blower or allow sufficient time for the roof to dry naturally. Removing any dust, dirt, or loose particles from the surface will help the Flex Seal Spray adhere properly and form a strong seal.

Applying Flex Seal Spray

Choosing the right weather conditions

It is crucial to choose the right weather conditions for applying Flex Seal Spray. Ideally, it is recommended to apply the spray on a clear, dry day with moderate temperatures. Avoid applying the spray during rainy or excessively hot conditions, as these can affect the drying process and the adhesion of the Flex Seal Spray. Following the manufacturer’s guidelines regarding permissible weather conditions is essential for a successful application.

Shaking the can before use

Before using Flex Seal Spray, shake the can thoroughly to ensure proper mixing of the product. This will help ensure consistency and maximize the effectiveness of the spray.

Holding the can at the correct distance

Hold the can of Flex Seal Spray at the recommended distance from the roof surface. This distance is typically specified on the can itself or in the product instructions. Holding the can at the correct distance ensures that the spray is applied evenly and prevents over application or pooling of the product.

Applying thin and even coats

When applying Flex Seal Spray, it is important to apply thin and even coats to the roof surface. Begin by applying a light first coat, ensuring full coverage of the desired area. Allow this coat to dry before applying additional coats as necessary. Applying thin and even coats helps to optimize the performance of the Flex Seal Spray and ensures a seamless finish.

Allowing proper drying time between coats

To ensure optimal adhesion and performance, it is crucial to allow each coat of Flex Seal Spray to dry fully before applying additional coats. Drying times may vary depending on weather conditions and the specific product used. Refer to the manufacturer’s instructions for recommended drying times and avoid rushing the process to maximize the effectiveness of the application.

Ensuring Proper Adhesion

Checking for adhesion issues

After applying Flex Seal Spray, it is essential to check for any signs of adhesion issues. Inspect the roof surface for peeling, flaking, or areas where the Flex Seal Spray has not adhered properly. Identifying these issues early on allows for prompt corrective action, ensuring the long-term effectiveness of the Flex Seal Spray.

Addressing poor adhesion

If there are any areas where the Flex Seal Spray has not adhered properly, it is important to address these issues promptly. Gently remove any loose or peeling sections of the coating using a scraper or a brush. Clean the area thoroughly and reapply the Flex Seal Spray, following the proper application steps to ensure proper adhesion.

Using additional adhesive if necessary

In some cases, additional adhesive or sealant may be necessary to enhance the adhesion of Flex Seal Spray. Consult with the manufacturer or a roofing professional for guidance on selecting and using suitable adhesive products. Applying additional adhesive can help strengthen the bond between the Flex Seal Spray and the roof surface, ensuring a secure and long-lasting seal.

This image is property of howlongdoesrooflast.com.

Regular Inspections and Maintenance

Creating a maintenance schedule

To maximize the lifespan of Flex Seal Spray on a roof, it is crucial to create a maintenance schedule. Regularly inspect the roof for any signs of damage, such as cracks or leaks, and schedule routine maintenance activities. By adhering to a maintenance schedule, homeowners can address any issues promptly, preventing further damage and extending the life of the Flex Seal Spray coating.

Inspecting the roof for damage

Regular inspections of the roof surface are essential to identify any potential damage or issues. Inspect the roof for cracks, leaks, or any signs of deterioration. Pay close attention to areas that are prone to wear and tear, such as flashing, seams, and joints. Identifying and addressing any damage early on can help prevent more significant issues and ensure the continued effectiveness of the Flex Seal Spray.

Repairing any small cracks or leaks

If during the inspection, small cracks or leaks are discovered, it is important to repair these issues promptly. Use appropriate roofing materials and techniques to seal and repair the damaged areas. This ensures that the roof remains watertight and prevents any further damage to the Flex Seal Spray or the underlying roof surface.

Protecting Flex Seal Spray from UV Exposure

Understanding the effects of UV radiation

UV radiation from the sun can lead to the degradation of certain roofing materials, including the rubberized coating of Flex Seal Spray. Over time, UV exposure can cause the coating to become brittle, crack, or peel, compromising its performance. Understanding the effects of UV radiation on the roof and the Flex Seal Spray helps homeowners take proactive steps to protect their investment.

Using UV protective coatings or sealants

To mitigate the damaging effects of UV radiation, homeowners can consider using UV protective coatings or sealants. These products are designed to provide an additional barrier against the sun’s harmful rays, extending the lifespan of the Flex Seal Spray. Applying a UV protective coating or sealant can help maintain the flexibility and integrity of the rubberized coating, maximizing its longevity.

Applying regular UV protectant treatments

Regular treatments with UV protectant products can also help protect the Flex Seal Spray from the harmful effects of UV radiation. These treatments can be applied periodically to maintain the UV resistance of the coating. Following the manufacturer’s instructions regarding treatment frequency and application techniques is essential to ensure optimal UV protection for the Flex Seal Spray.

This image is property of gudgear.com.

Dealing with Extreme Weather Conditions

Preparing for heavy rain or snow

Heavy rain or snow can put additional stress on the roof and the Flex Seal Spray coating. To prepare for extreme weather conditions, ensure that the roof is structurally sound and can withstand the added weight. Clear any debris or potential obstructions from gutters and drains to facilitate proper water flow. Regularly inspect the roof after heavy rain or snowfall to identify any potential damage that may require repair or maintenance.

Protecting against high winds

High winds can be particularly damaging to roofs, potentially causing the Flex Seal Spray to lift or peel. To protect against high winds, ensure that the Flex Seal Spray is applied correctly, with proper adhesion to the roof surface. Additionally, regularly inspect the roof for any signs of loose or damaged areas, such as loose shingles or flashing. Reinforcing any weak areas or addressing potential issues promptly helps protect the Flex Seal Spray from wind damage.

Addressing extreme temperature fluctuations

Extreme temperature fluctuations can cause the roof and the Flex Seal Spray coating to expand and contract, potentially leading to cracks or other damage. To address extreme temperature fluctuations, ensure that the roof has proper insulation and ventilation. Adequate insulation and ventilation help maintain a stable temperature, reducing the potential for damage to the Flex Seal Spray and extending its lifespan.

Avoiding Common Mistakes

Overapplying Flex Seal Spray

One common mistake when using Flex Seal Spray is overapplying the product. Overapplying can result in uneven areas, excessive thickness, or pooling, which can affect the performance and longevity of the coating. It is important to follow the manufacturer’s instructions regarding the recommended number of coats and application techniques. Applying the product as directed ensures even coverage and optimal results.

Not following the proper application steps

Another common mistake is not following the proper application steps. Each product may have specific instructions regarding shaking the can, recommended distances, and drying times between coats. It is crucial to read and follow the manufacturer’s instructions carefully to ensure the best results and maximize the effectiveness of the Flex Seal Spray.

Ignoring maintenance and inspections

Neglecting regular maintenance and inspections can significantly impact the effectiveness and lifespan of Flex Seal Spray on a roof. By ignoring these essential activities, homeowners risk overlooking potential issues that may worsen over time. Regular inspections and maintenance help identify and address problems promptly, extending the life of the Flex Seal Spray coating and ensuring long-term protection for the roof.

This image is property of gudgear.com.

Testing and Evaluation

Periodic roof performance testing

Periodic roof performance testing can help assess the condition of the Flex Seal Spray coating and the overall roof structure. This testing involves inspecting the roof for any signs of leaks, damage, or problems. Conducting these tests at regular intervals, such as annually or biannually, allows homeowners to detect any deterioration or issues early on, enabling timely repairs or maintenance.

Evaluating the condition of Flex Seal Spray over time

Evaluating the condition of Flex Seal Spray over time is essential to gauge its effectiveness and lifespan. Regularly inspect the roof surface and the Flex Seal Spray coating for any signs of cracking, peeling, or other damage. Document the condition and take appropriate action if necessary, such as reapplying the product or addressing any adhesion issues. Monitoring the condition of the Flex Seal Spray helps homeowners make informed decisions regarding maintenance, repairs, or potential reapplication.

Addressing any signs of deterioration

If signs of deterioration are detected during testing or evaluation, it is important to address these issues promptly. Small cracks or areas of damage should be repaired promptly using suitable roofing materials and techniques. Adequate maintenance and adjustments help extend the lifespan of the Flex Seal Spray on the roof, ensuring continued protection and minimizing the risk of further damage.

Conclusion

In summary, Flex Seal Spray is a versatile and durable waterproofing solution for roofs. By understanding how to properly use and maintain Flex Seal Spray, homeowners can maximize its lifespan and ensure long-term protection for their roofs. Through proper surface preparation, correct application techniques, regular inspections, and proactive measures against UV exposure and extreme weather conditions, Flex Seal Spray can provide a reliable and effective solution to seal and protect roofs for years to come. By following the outlined steps and taking proactive maintenance measures, homeowners can take full advantage of the benefits offered by Flex Seal Spray and enjoy a watertight and long-lasting roof.

This image is property of howlongdoesrooflast.com.