Flex Seal has garnered significant attention as a possible solution for various household repairs, but is it truly a reliable fix? Many individuals have sought to determine if this remarkable product delivers the results it promises. The article explores the effectiveness of Flex Seal as a permanent solution, aiming to provide valuable insights and guidance for those considering this innovative repair option. Whether you’re dealing with leaky pipes or cracks in your flooring, you’ll find this article to be an informative resource in your quest for a reliable solution.

This image is property of i.ytimg.com.

What is Flex Seal?

Overview of Flex Seal

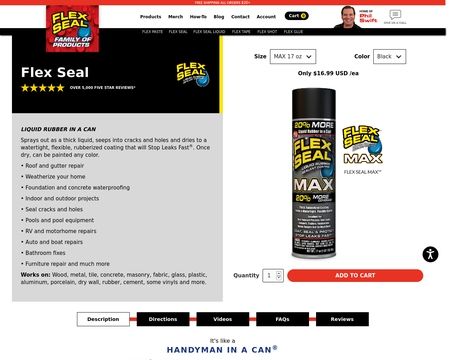

Flex Seal is a popular line of products specifically designed for sealing and repairing various surfaces. It is known for its versatility, durability, and efficiency in fixing leaks, sealing cracks, and preventing damage caused by water and moisture. Flex Seal is a liquid rubber sealant that effectively bonds to surfaces, providing a protective barrier that is resistant to extreme weather conditions.

Types of Flex Seal products

Flex Seal offers a range of products that cater to different needs and application methods. The most common types of Flex Seal products include Flex Seal Liquid, Flex Seal Spray, Flex Seal Tape, and Flex Seal Liquid Rubber in a can. Each product is formulated to be easy to use and provides a flexible, strong seal that can withstand harsh environmental conditions.

How does Flex Seal work?

Flex Seal works by creating a watertight seal when applied to the surface. The liquid rubber in Flex Seal molds and adheres to the surface, forming a protective barrier that prevents leaks or further damage. When it dries, it becomes a flexible, rubberized coating that expands and contracts with the surface, allowing it to withstand the natural movements of different materials.

Benefits of Using Flex Seal

Versatility in application

One of the major benefits of using Flex Seal is its versatility in application. It can be used on a wide range of surfaces, including metal, wood, concrete, plastic, fabric, and more. Whether it’s a leaky roof, a cracked foundation, or a damaged pipe, Flex Seal can provide a reliable solution for various repair needs.

Efficiency in sealing various surfaces

Flex Seal is highly efficient in sealing different surfaces. Its liquid rubber formula allows it to penetrate and fill in cracks and gaps, providing a strong and durable seal. Whether it’s a small leak or a larger repair, Flex Seal can effectively seal off the area and prevent further damage or water intrusion.

Resistance to extreme weather conditions

Flex Seal is designed to withstand extreme weather conditions. Whether it’s heavy rain, snow, or intense heat, Flex Seal’s rubberized coating remains intact and does not degrade. This resistance to changing weather conditions ensures that the seal remains effective for a long time, providing reliable protection against leaks and other issues.

Common Uses for Flex Seal

Fixing leaks in roofs and gutters

One common use for Flex Seal is fixing leaks in roofs and gutters. The liquid rubber formula of Flex Seal makes it easy to apply to the affected areas, providing an instant, long-lasting solution for leaks. It can be used on different types of roofs and gutters, including shingles, metal, and PVC, effectively sealing off any cracks or damaged areas.

Sealing cracks in foundations

Flex Seal is also commonly used for sealing cracks in foundations. The flexible and rubberized nature of the product allows it to effectively fill in and seal the cracks, preventing water intrusion and potential structural damage. This is particularly beneficial in areas with high water tables or where the foundation is prone to movement.

Repairing damaged pipes or hoses

Flex Seal is an excellent choice for repairing damaged pipes or hoses. Its rubberized form allows it to bond tightly to the surface, creating a strong seal that prevents leaks. Whether it’s a small crack or a larger break, Flex Seal can provide a temporary or even a permanent fix, reducing the need for costly replacements.

Effectiveness of Flex Seal

Long-lasting durability

Flex Seal is known for its long-lasting durability. Once applied, it forms a strong and flexible seal that can withstand the test of time. Many users have reported that their Flex Seal repairs have held up well for years, even in demanding conditions. This longevity makes it a reliable solution for both temporary and permanent fixes.

Resistance to water and moisture

One of the key advantages of Flex Seal is its resistance to water and moisture. Once cured, Flex Seal creates a barrier that is impervious to water, preventing leaks and damage caused by moisture. This makes it particularly suitable for applications in areas prone to frequent exposure to water, such as bathrooms, basements, or outdoor structures.

Flexibility in expanding and contracting

Flex Seal’s flexibility to expand and contract with the material it is applied to is another important characteristic. It can accommodate natural movements in different surfaces, such as temperature fluctuations or structural shifts, without compromising the integrity of the seal. This flexibility ensures that the bond remains intact and prevents cracks or leaks from occurring.

This image is property of i.ytimg.com.

Limitations of Flex Seal

Not suitable for certain surfaces

While Flex Seal is versatile, it may not be suitable for certain surfaces such as fabrics, unpainted concrete, or surfaces that require a strong mechanical bond. It is important to read and follow the manufacturer’s recommendations and test a small area before applying Flex Seal to ensure compatibility with the specific surface.

Limited strength for heavy-duty repairs

Flex Seal is primarily designed for smaller repairs and may not have the strength required for heavy-duty applications. For example, if you need to repair a large hole or a heavily damaged surface, Flex Seal may not provide a suitable long-term solution. In such cases, it is advisable to consult a professional or explore alternative repair methods.

Potential for peeling or cracking over time

In certain circumstances, Flex Seal may peel or crack over time, especially if the surface experiences significant movement or expansion/contraction. While the product is generally durable, continuous stress or exposure to harsh conditions can affect its performance. Regular inspection and maintenance are recommended to identify any potential issues and address them promptly.

Customer Reviews and Opinions

Positive experiences with Flex Seal

Many customers have had positive experiences with Flex Seal. They have reported successful repairs of leaks, cracks, and other damage using the different Flex Seal products. Customers appreciate the ease of use, versatility, and durability of the product. Positive reviews often highlight Flex Seal’s ability to provide quick, effective fixes without the need for extensive tools or expertise.

Negative experiences with Flex Seal

While the majority of customers have had positive experiences, some have reported negative experiences with Flex Seal. Complaints often revolve around limited effectiveness in certain applications or difficulties in achieving a proper seal. It is important to note that individual experiences may vary, and it is essential to follow the instructions and guidelines provided by the manufacturer for optimal results.

Comparisons to alternative products

Flex Seal is often compared to alternative products on the market, such as caulks, tapes, or other sealants. Some users find that Flex Seal offers a more versatile and convenient solution, while others prefer alternative methods for specific repairs. It is advisable to consider factors such as surface type, repair requirements, and personal preferences when choosing between Flex Seal and other products.

This image is property of www.therip.com.

Applying Flex Seal

Preparation of the surface

Before applying Flex Seal, it is crucial to prepare the surface properly. This typically includes cleaning the area to remove dirt, debris, and any loose materials. Smooth out any rough surfaces, and ensure the area is dry before application. Following the manufacturer’s instructions is essential for preparing the surface correctly and maximizing the effectiveness of the seal.

Step-by-step application process

To apply Flex Seal, start by shaking the can or container well to ensure even distribution of the product. Hold the can approximately eight to twelve inches away from the surface and apply a thin, even coat. For larger repairs or multiple coats, allow each layer to dry completely before applying the next. Follow the manufacturer’s recommended drying time and temperature guidelines for best results.

Tips for achieving the best results

To achieve the best results with Flex Seal, it is essential to apply the product following the manufacturer’s instructions precisely. Some additional tips for optimal results include:

- Apply multiple thin coats rather than one thick coat.

- Hold the can or container at a consistent distance from the surface during application.

- Allow the product to cure fully before exposing it to water or other environmental elements.

- Test the product on a small inconspicuous area before applying it extensively.

- Store the product according to the manufacturer’s recommendations to maintain its effectiveness.

Safety Considerations

Proper ventilation when using Flex Seal

When using Flex Seal, it is important to ensure proper ventilation in the area of application. This will help to minimize exposure to fumes and provide a healthier environment for both the user and the surrounding space. Adequate ventilation can be achieved by opening windows, using fans, or working in outdoor areas when possible.

Avoiding contact with eyes and skin

To prevent any potential harm, it is crucial to avoid contact with eyes and skin when using Flex Seal. Wear appropriate protective gear such as gloves and safety goggles to protect against accidental contact. In case of contact, rinse the affected area thoroughly with water and seek medical assistance if necessary.

Storage and disposal recommendations

Flex Seal should be stored in a cool, dry place, away from open flames or excessive heat. It is essential to follow the manufacturer’s recommendations for proper storage to maintain the product’s effectiveness. When disposing of unused or empty containers, adhere to local regulations and guidelines for safe disposal of household chemicals.

This image is property of d1gzz21cah5pzn.cloudfront.net.

Cost and Availability

Price range of Flex Seal products

The price range for Flex Seal products varies depending on the type and size of the product. Liquid formulas and spray cans are generally more affordable, with prices ranging from $10 to $30. Flex Seal Tape and Flex Seal Liquid Rubber in a can often have slightly higher costs, ranging from $15 to $40.

Where to purchase Flex Seal

Flex Seal products can be purchased at a variety of retail stores, including home improvement stores, hardware stores, and online retailers. Popular options for purchasing Flex Seal include stores like Walmart, Home Depot, Lowe’s, and the official Flex Seal website.

Comparison of cost versus benefits

When considering the cost of Flex Seal products, it is important to weigh the benefits against the price. Flex Seal offers a cost-effective solution for many repairs, eliminating the need for costly replacements or professional services. Additionally, the durability and versatility of Flex Seal contribute to its overall value, making it a reliable option for various sealing and repair needs.

Expert Opinions on Flex Seal

Insights from professionals in relevant industries

Professionals in relevant industries, such as construction, plumbing, and home repair, have provided insights on Flex Seal and its effectiveness. Many professionals acknowledge Flex Seal as a valuable product for smaller repairs and preventive maintenance. They highlight its ease of use, versatility, and effectiveness in sealing and preventing leaks.

Analysis of the product’s reliability

Experts have conducted various analyses to assess the reliability of Flex Seal. These assessments often include testing the product’s performance under different conditions and comparing it to alternative solutions. While individual test results may vary, Flex Seal consistently demonstrates a strong resistance to water intrusion, durability, and long-lasting effectiveness.

Research studies and test results

Research studies and test results further support the effectiveness of Flex Seal. These studies often examine different aspects, such as the product’s ability to prevent leaks, withstand weather conditions, and maintain a strong bond over time. Results consistently show that Flex Seal performs well in these areas and provides reliable protection against various forms of damage.

In conclusion, Flex Seal is a versatile, durable, and efficient solution for sealing and repairing various surfaces. Its liquid rubber formula, combined with its ability to resist extreme weather conditions, makes it a reliable choice for fixing leaks, sealing cracks, and repairing damaged pipes or hoses. While Flex Seal may have limitations and individual experiences may vary, it remains a popular option due to its long-lasting durability, resistance to water and moisture, and flexibility in expanding and contracting. It is important to follow the manufacturer’s instructions for application and consider safety precautions when using Flex Seal. With its cost-effectiveness and availability in various retail stores, Flex Seal provides a convenient and reliable solution for a multitude of repair needs.

This image is property of i.ytimg.com.